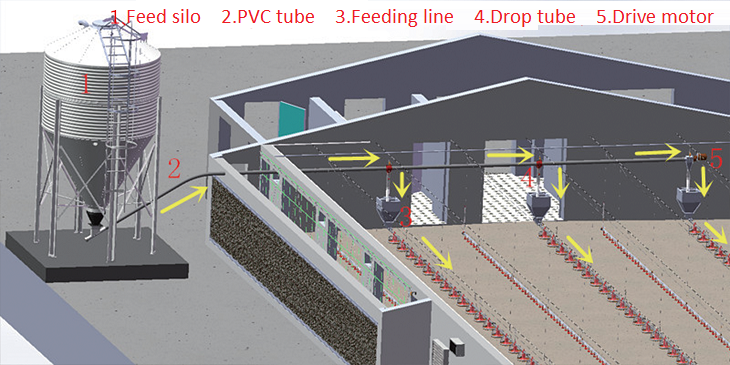

Part 1: Main Silo or Hopper Feeding System

It is a complete set of automatic feeding system, including a material conveying pipe, silo, auger, drive motor and a material level sensor. This system is to deliver the feed from silo to each hopper in the poultry house, and then deliver the feed from hopper to each small pan assembled in line. The sensor at the end of the main feed line, which automatically controls the motor on and off to release automatic delivery. Feed silo's capacity is from 2tons to 22tons which depends on your chicken house design and the quantity of the raising chicken.

The feed is stored in the silo, in order to save large amount of package, as well as to ensure the health of feed. There are different specifications of silos which are alternative to choose according to the daily consumption in the chicken house. Material of silo consists of galvanized sheet and glass fiber reinforced plastic.

If you just build one or two chicken house and your house size is not too large, then we suggest you to use (manpower) hopper instead of silo to save cost.

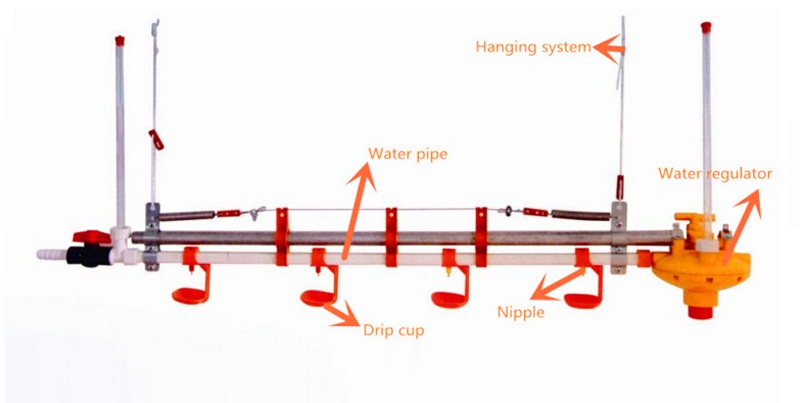

Part 2: Automatic Nipple Drinking System

This system provides fresh and clean water for poultry which is crucial for the growth of poultry. The drinkers can be triggered from 360 degree which helps young chicken start well and makes drinking easier.

The Nipple Drinking System has been typically used by professional chicken farmers for many years. No more poop in water. No spiling and soaking the nesting material so the chickens can get nature gravity fed by fresh, as well as clean water without dieases.

Part 3: Ventilation and Cooling System

This system controls climate conditions, fresh air, humidity and temperature in poultry shed. It is vital for growing chicken. This system includes poultry house fan, cooling pad and air inlet window.