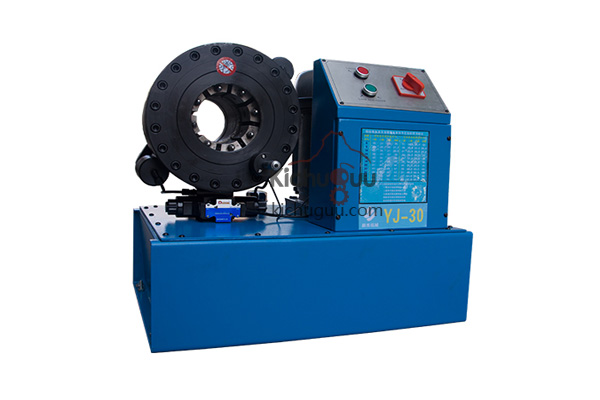

Product Description

Main Features

1) Using forge steel machine head, this kind of steel is more durabler than general steel.

2) Simple controls and operation.

3) High crimp accuracy, precise adjusted through a micrometer.

4) Foot pedal: free hand operate.

5) Magnetic dies (Patented), very convenient to remove and install dies.

Product Application

Hose crimping machine is mainly used for crimping processing for high pressure hydraulic hose assembly in the mechanical engineering. It can also be used for crimping steel pipes, especially large pipes and irregular shape pipes. This machine features small and portable appearance, big force, low noise and easy to operate. The crimping range can be precise adjusted through a micrometer. It makes the mould base division to be more even through the double inclined plane eight-flap mould seat equipped with a high accuracy guiding device.

Main part:

1、Machine Head

Attribute: Forge Steel

Front cover, cylinder and piston use Chrome40, forging integrity, increase its fatigue resistance. Surface hardness is HRC26-30°, hardness of inside layer is HRC59-63°, Eht 2mm.

2、Dies & Mold Base

Attribute: Strong Magnetic Connection

Dies and die base is connected by cutting-the-edge technology of strong magnetic connection.

3、Electromagnetic Valve

Attribute: 39.852N Pushing Force

It is used to adjust the hydraulic oil flow direction, quantity, speed etc. With high precision and good flexibility. The reversing valve spool is original Germany SED. Working with stability, no shaking, no blocking.