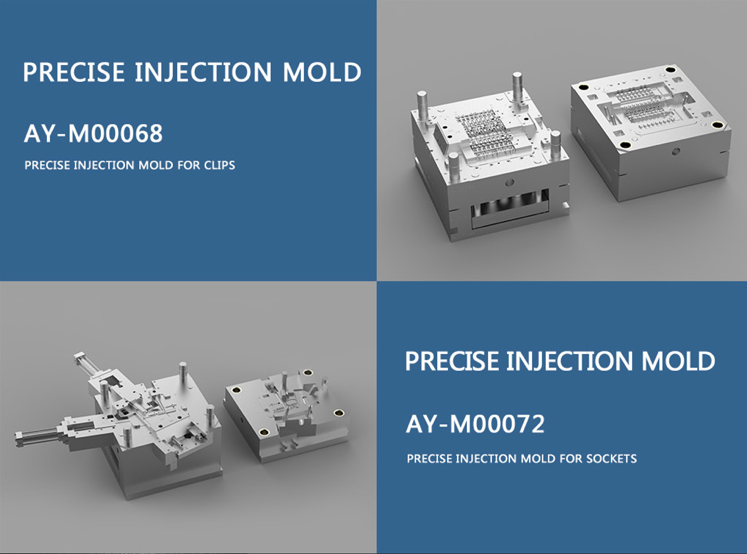

Injection Mold

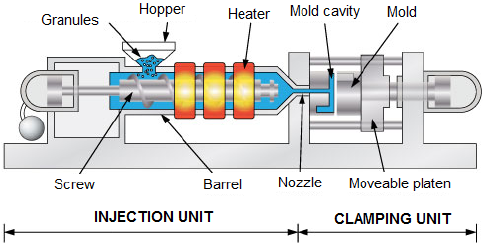

Things to pay attentinon while choosing injection mold machine for your factory

- The size of your end product

- Thickness of the walling

- above two will determine the size of the machine, normally measured by compressing tonnage and cavity size

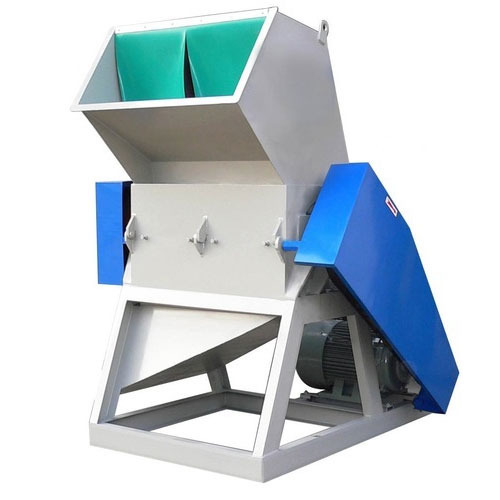

Crushers

Crusher are important because all fault product will be crusher and material recycled immediately, again choose crushers according to your product size and and the wall thickenss (hardness ) of the product

Chillers, Mixers and other auxiliary equipments

The plastic extrution requires high heating and fast cooling, to increase efficiency it is recomended to install a chiller and cooling tower, on top of a cooling dam, water recycling system need to be installed;

Also you will need a mixer to mix color masterbach with with the material to get uniformity of color in the broduct

remember to ask your supplier about all other secondary equipment you might need, most of them are optional but increase efficiency and quality of the product.

Mold

Each product you going to make requires a different set of mold (different sizes also require different mold)